our product

- Brass Neutral Links

- GI Box

- Neutral Bars

- Brass Earthing Components

- Brass Terminal Blocks

- Brass Electrical Fittings

- Brass Terminal Bars

- Brass Earth Blocks

- Panel Board Accessories

- Brass Fasteners

- Brass Cable Glands

- Brass Grounding Clamps

- Copper Bonded Earthing Rods

- Brass Battery Terminals

- Brass Line Taps

- Brass Connectors

- HRC Fuse Connectors

- Brass Electronic Connectors

- Brass Split Bolts

- Brass Pin Electrical Plugs

- Electrical Switch Gear Parts

- Conduit Junction Boxes

- Brass Grounding Clamps

- Grounding Connectors

- Brass Socket Pins

- PCB Teminals

- Brass Spacer and Pillars

- Cable Cleats

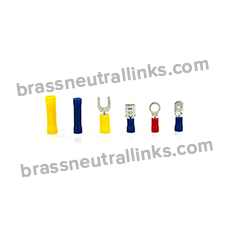

K-Spec Crimp Terminals

Brass Neutral Links manufacture and export K-Spec Crimp Terminals with high quality and international standards. K-Spec Crimp Terminals have groove serrations to provide maximum contact and tensile strength after crimping. These type of Crimp Terminals are color coded in Industry standards.

Following are the specification for K-Spec Crimp Terminals.

| Material for K-Spec Crimp Terminals |

|

|---|---|

| Plating and Coating for K-Spec Crimp Terminals | Natural, Nickel Plated, Tin Plated Brass, Electro-Tin, Chrome or any coating as per customer requirements. |

| Threading Available for K-Spec Crimp Terminals |

|

| Application for K-Spec Crimp Terminals |

|

| Features for Butt Splices Terminals |

|

We can manufacture and export K-Spec Crimp Terminals as per specifications (custom drawing and samples) for more information please Contact us